TORRE JALISCO

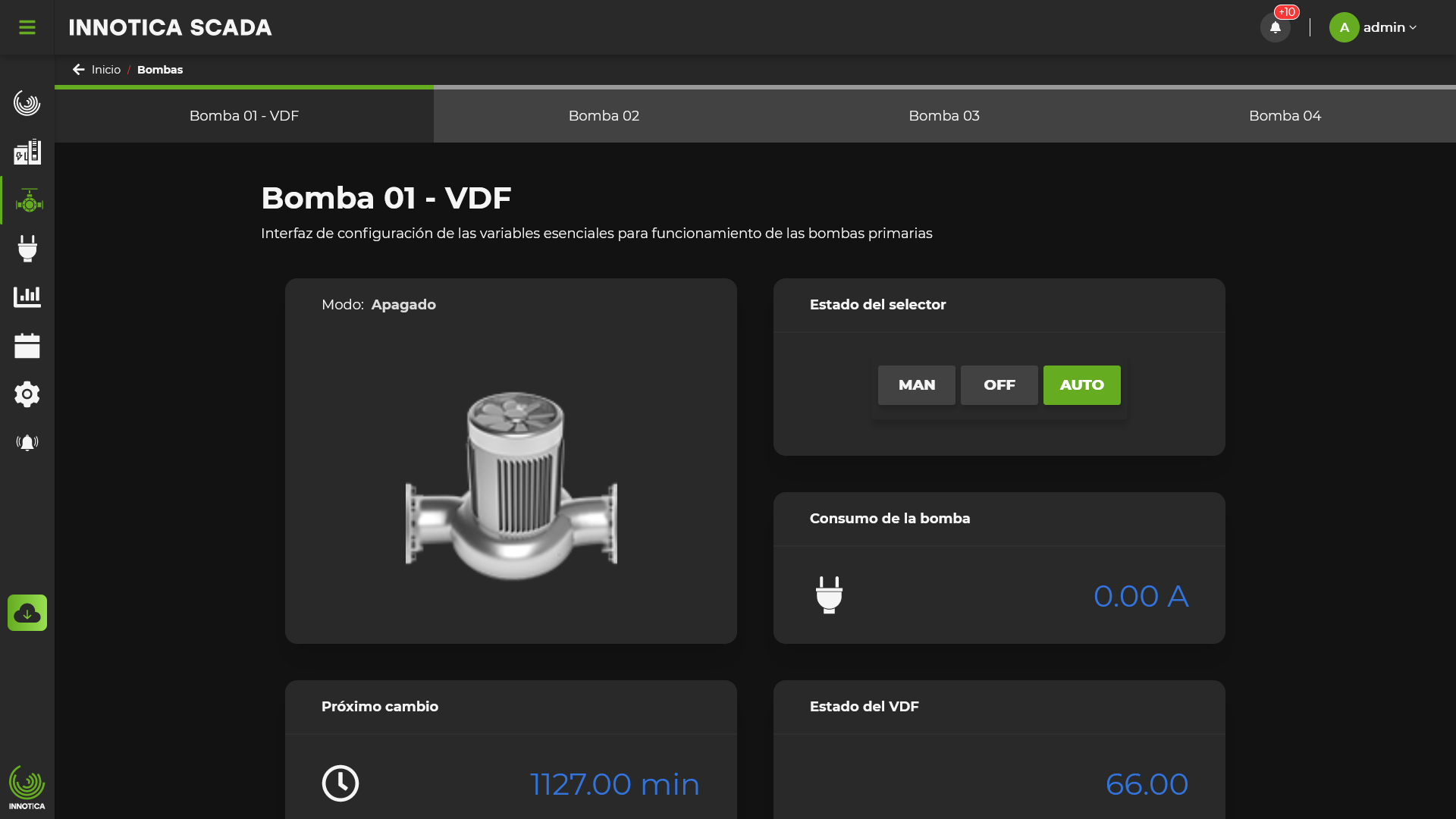

Monitoring and control of the tower's chilled water plant. This project integrates 3 air-cooled Midea brand chillers, 1 VFD, 1 power network analyzer and 3 constant speed primary pumps.

The client's need

The owner wanted to reduce the dependency on personnel assigned to locally monitor the chilled water plant operation, avoid having to troubleshoot chiller failures due to poor power quality, long service interruptions when the emergency power plant started, and end the poor practice of operating without information about equipment operation and chilled water plant parameters.

Plant diagnostic visit

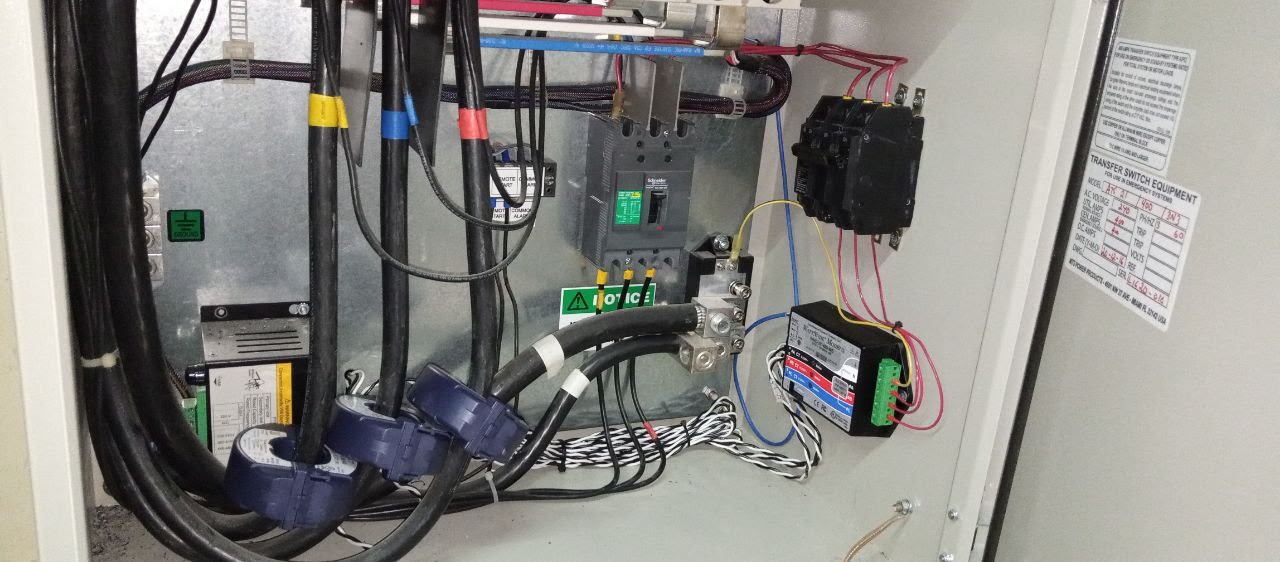

Thanks to the recommendation from the chiller supplier, CozyCool, it was possible to visit the existing chilled water plant and establish the relationship between the end client and Innotica. During the site visit, it was observed that the plant had 3 air-cooled Midea brand chillers without communication gateways, 3 constant speed pumps and 1 variable frequency drive pump. Additionally, the need to include motorized valves for the incorporation and removal of each chiller was identified. These units were powered from a transfer switch (ATS) receiving power from Corpoelec and an emergency power plant with limited capacity for only 1 chiller and 2 pumps.

The construction process

Based on the need and existing infrastructure, the Polaris automatic monitoring and control product was proposed, a solution that could identify the power supply source by integrating the ATS, measuring and recording power quality. Based on this analysis, the operation sequence was automated for both startup and shutdown of the plant for the 2 power supply scenarios, also allowing alternation of chiller and pump operation, along with recording of temperature and pressure for both supply and return chilled water. Additionally, chiller integration was considered by leveraging Modbus RTU communication between the chiller's main card and its own configuration display.

A project that contributes to the goal of being a smart building

The project allowed the client to eliminate an operational problem in the tower and improve the quality of service provided to tenants and office owners in the infrastructure, also obtaining a tool to support marketing for the commercialization of the tower's sellable spaces with offices and commercial premises.

Project achievements

Among the most important achievements of the project are the following:

- Automation of the startup, shutdown, rotation and thermal capacity increase process of the plant.

- Monitoring and recording of the quality and quantity of energy consumed in the plant.

- Monitoring and recording of the temperature and pressure differential of the plant.

- Integration for monitoring and control of each chiller, thereby measuring all operational parameters of each machine, including alarms and/or notifications provided by the equipment.

- Recording of operating time for each pump and chiller in the plant, with the objective of promoting predictive maintenance and avoiding corrective maintenance.

- Inclusion of a solution where manuals, technical documents and plans of the chilled water plant are located.

If you would like more information about the product supplied for this project, we invite you to visit the product page Polaris.