CENTRO FINANCIERO MADRID

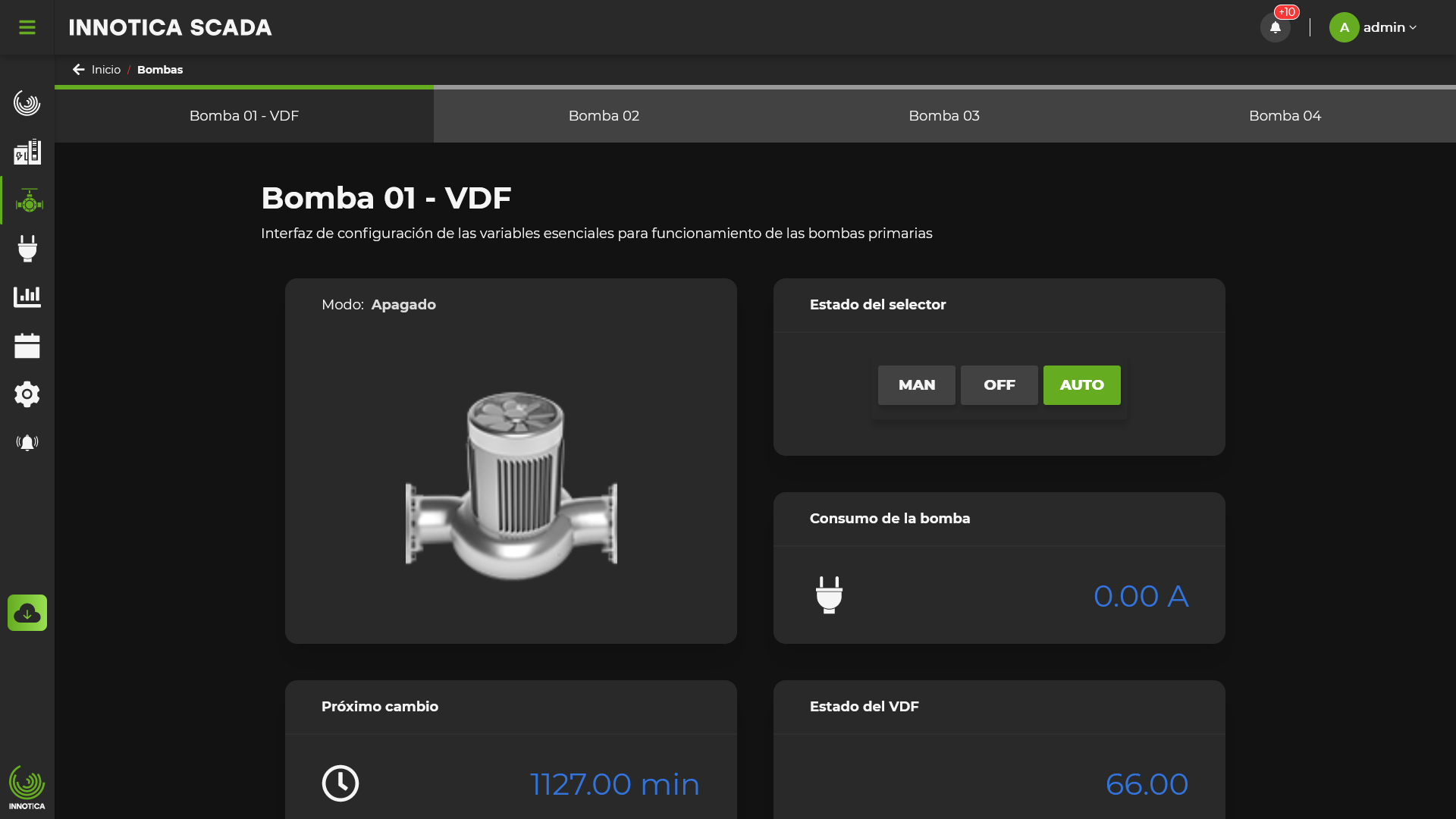

Monitoring and control of the tower's chilled water plant. This project integrates 3 air-cooled Carrier brand chillers, 4 constant speed pumps and a power network analyzer.

The desire to digitalize operations and maintenance

The digitalization of a company's operational processes and its infrastructure is an innovation strategy that increases asset value, optimizes resource usage and ensures operational continuity. With this objective, the tower owner contacted us to digitalize the most important system in the infrastructure, the chilled water plant of the HVAC system.

The existing chilled water plant

During the first visit to the existing infrastructure, a chilled water plant was found consisting of 3 Carrier brand air-cooled chillers without communication cards, 4 constant pressure pumps, and 1 bypass valve controlled by differential pressure. This chilled water plant was manually controlled by operations and maintenance staff who rotated the chillers every few days.

The service proposal

Based on the reality of the existing infrastructure, the Polaris automatic monitoring and control product was proposed, a solution that would constantly measure and record the plant parameters, chillers, pumps and power quality, all together with the supply, configuration and installation of the communication card for each Carrier chiller.

Facilitating infrastructure operations and maintenance

The project allowed the client to eliminate an operational problem in the tower and improve the quality of service provided to tenants and office owners in the infrastructure, also obtaining a tool to support marketing for the commercialization of the tower's sellable spaces with offices and commercial premises.

Project achievements

Among the most important achievements of the project are the following:

- Automation of the startup, shutdown, rotation and thermal capacity increase process of the plant.

- Monitoring and recording of the quality and quantity of energy consumed in the plant.

- Monitoring and recording of the temperature and pressure differential of the plant.

- Integration for monitoring and control of each chiller, thereby measuring all operational parameters of each machine, including alarms and/or notifications provided by the equipment.

- Recording of operating time for each pump and chiller in the plant, with the objective of promoting predictive maintenance and avoiding corrective maintenance.

- Inclusion of a solution where manuals, technical documents and plans of the chilled water plant are located.

If you would like more information about the product supplied, we invite you to visit the product page Polaris.