Teresa Carreño Theater

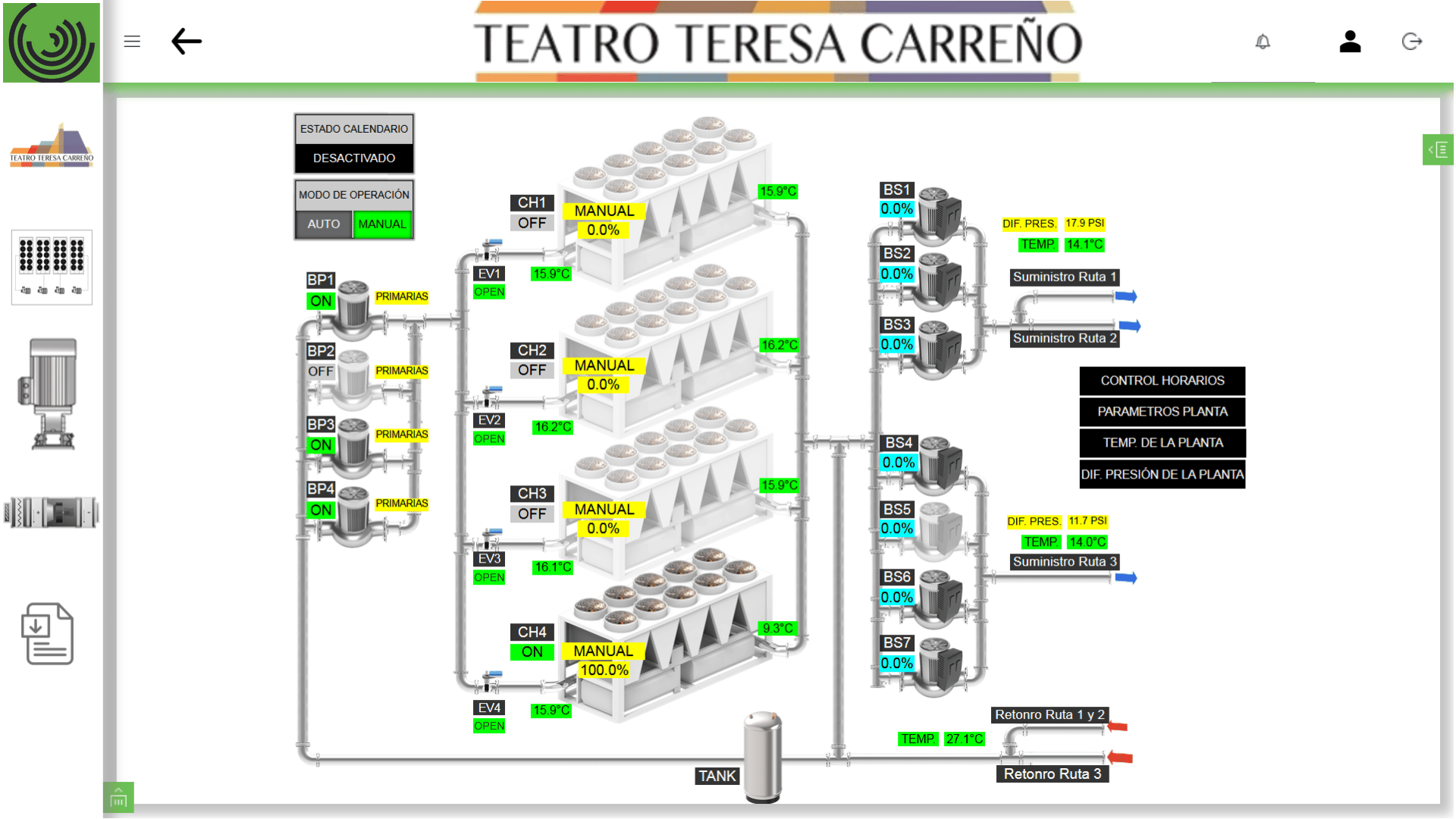

Monitoring and control of the theater's chilled water plant and AHUs, integrating 4 air-cooled Midea brand chillers, 4 primary pumps, 7 variable secondary pumps and 29 AHUs.

Innovation in an iconic project

During a process of recovery and updating of the various areas and systems of this renowned infrastructure in our country, we were contacted by the HVAC equipment supplier who asked us to design, install and commission a monitoring and control system for the operation of the theater's chilled water plant and AHUs.

HVAC system description

The HVAC system would consist of 4 air-cooled Midea brand chillers, 4 constant pressure primary pumps and 7 pumps with their respective VFDs. This plant would feed 29 indoor units, including 26 AHUs and 3 FCUs. The end client's requirement was to have a monitoring and control system that would facilitate operations and maintenance and innovate in the operation process of this system.

The supplied system

To meet this need, a control system was designed consisting of equipment with BACNET IP and BACNET MS/TP communication. These elements would monitor and control the system components, leveraging current sensors, temperature and pressure sensors, while simultaneously controlling the position of the proportional valve located in each AHU room and the on/off valves located in the chilled water plant. In each AHU room, elements are located that allow controlling the equipment inside the mechanical room.

The Result

The solution generated a monitoring and control platform that enables management of system components, recording information related to chilled water plant and AHU parameters. Schedule-based control, setpoint modification and remote on/off are some of the many features of this comprehensive HVAC monitoring and control solution.

Project achievements

Among the most important achievements of the project are the following:

- Monitoring of pumps, chillers, temperature and pressure differential of the chilled water plant.

- Monitoring and recording of the temperature and pressure differential of the plant.

- Integration for monitoring and control of each chiller, thereby measuring all operational parameters of each machine, including alarms and/or notifications provided by the equipment.

- Automatic monitoring and control of the AHUs.

- Inclusion of a solution where manuals, technical documents and plans of the chilled water plant are located.

If you would like more information about the product supplied for this project, we invite you to visit the product page Polaris.